eISSN: 2093-8462 http://jesk.or.kr

Open Access, Peer-reviewed

eISSN: 2093-8462 http://jesk.or.kr

Open Access, Peer-reviewed

Yeon Pyo

, Myoung Hwan Park

, Byung Yong Jeong

10.5143/JESK.2017.36.3.221 Epub 2017 June 24

Abstract

Objective: The purpose of this study is to draw the accident prevention model using the signal detection theory, and to implement accident prevention program, based on a health promotion and support activities in a shipbuilding company.

Background: Workers' health management is perceived important from the human resource management perspective, as well as from the personal perspective.

Method: This study developed an accident prevention model by analyzing the correlation between 704 workers' health examination variables, and reviewed the verification of the model through a follow-up survey on the control variables and status of hazards targeting 650 workers for four years from 2007 to 2010. Also, a health promotion program was implemented targeting a production division to improve alcohol habits, smoking, musculoskeletal pain complaints and hearing control indices, which are the control variables of the model.

Results: As a result of four years' implementation, the following effects were obtained: the days away from work fell 87.5%, and accident rate dropped 71.5% in 2010, respectively, compared to 2006, before the activity was implemented.

Conclusion: This study shows that the accident prevention activities based on workers' health promotion activities are effective to prevent industrial accidents and injuries.

Application: The research findings will serve as a practical guideline for establishing preventive measures in the shipbuilding company.

Keywords

Shipbuilding industry Safety and health Accident prevention Signal detection theory Health support program

Workers' health management is perceived important from the human resource management perspective, as well as from the personal perspective, and the paradigm on workers' safety and health is shifting to a prevention-focused paradigm. Therefore, companies execute health promotion programs, after they perceive that an illness control and health promotion program through proper everyday life habits correction is important for workers' productivity improvement. Those companies make efforts to fundamentally prevent occupational illnesses by monitoring exposures to hazard factors causing workers' illnesses, evaluating the symptoms of the workers exposed to risk factors and applying the evaluation results to work environment improvement.

Worker's physical examination has an industrial health service function to protect workers' health, and a function to protect exposure to harmful materials and prevent diseases. Physical examination results are also used for follow up examination and treatment of the abnormal health, in addition to administrative actions including wearing protective gear, adjustment of working hours, treatment and returning to work and duty conversion.

Absence from work, occupational accidents and injuries are closely associated each other, and they can cause the decline of workers' health and productivity. In this regard, the identification of their causal relationship or correlations can be an important subject. Much budget is invested to conform to business owners' obligations specified in the Industrial Safety and Health Act including health examination in workplaces. However, physical and safety examination indices, such as physical examination results, the job stress, musculoskeletal disorder complaints, health status and everyday life habits, are not utilized as basic data to prevent industrial accidents in workplaces.

Human factors, such as alcohol habits (Dawson, 1994; Henderson et al., 2005; Oldenburg et al., 2010), heavy smoking (Sacks and Nelson, 1994; Chiolero et al., 2006), lifestyle (Hansen and Pedersen, 1996), and fatigue (Hanecke et al., 1998; Janssen et al., 2003; Swaen et al., 2003; Torres-Harding et al., 2002) experienced by workers in life at work, function as major causes to absence from work or job transfer, and they also reduce productivity, and become a cause of an accident (Gordon et al., 2005). Job stress has relevance with cardiovascular diseases or musculoskeletal disorders, as well as psychiatric diseases, and is known that job stress can be directly involved in workers' diseases, absence from work and leaving workplace during working hours (Lamontagne et al., 2007). In Europe, financial burden, due to absence from work arising from psychiatric diseases, accounts for 3~4% of GNP annually (Henderson et al., 2005), and there is a study result reporting that absence from work due to stress-related diseases take up 60% of the total absence from work (Kearns, 1986).

There are diverse and complex works conducted to build ships in the shipbuilding industry, and workers are known to work lots of hours in inappropriate working postures in the confined or narrow spaces (Lee, 2012; Jeong et al., 2012; Kim, 2012; Pyo and Jeong, 2007). Health promotion or accident prevention activities to ensure workers' safety and health can be really needed and important (Choi et al., 2012; Jeong and Kim, 2012; Pyo and Jeong, 2007). Pyo and Jeong (2010) drew five control factors, such as fatigue, musculoskeletal disorder complaints, alcohol habits, heavy smoking and hearing loss, by comprehensively analysing the association among physical examination results, job stress evaluation and musculoskeletal disorder complaints. They actually insisted the development of a health promotion and support program for the workers concerned for their health control in the shipbuilding industry. This study is a follow up study of Pyo and Jeong (2010), and presents the development of an accident prevention model using the five safety and health indices, and accident prevention cases based on the health promotion and support program.

2.1 Development of an accident prevention model

Pyo and Jeong (2010) examined the correlations among everyday life habit index, physical health index and mental health index, identified the indices related with accident occurrence, and used them as control variables on safety and health activities. This study aimed to develop an accident prevention model using five control factors, which are five safety and health indices, namely fatigue, musculoskeletal pain complaints, alcohol habits, heavy smoking and hearing loss.

To select meaningful variable combinations among the five safety and health indices, this study drew the accident prevention and control models with five factors, four factors and three factors targeting 704 workers, based on 2006. In the model development process, this study selected practical variables and the numbers of the variables by analysing the correlation with the status of hazards in terms of the 704 workers' safety and health indices.

2.2 Verification of model and implementation of accident prevention program

This study reviewed the verification of the developed model through follow up survey on the status of hazards for four years from 2007 to 2010 targeting the 650 uninjured workers.

The health promotion and support activities to manage five safety and health indices were executed from 2007 targeting a separate specific division of a shipbuilding company as well as the review of model verification by the follow up survey. The subjects to implement the activities were some 900 workers at a production division of a shipbuilding company, and the accident prevention activities were implemented, based on the workers' health promotion support program. To analyse the accident prevention model's effects, this study analysed the accident prevention effects by comparing the change in safety indices including days away from work and accident rate for four years from 2007 to 2010, setting up 2006 as the comparison year before the accident prevention activities were implemented.

3.1 Development of an accident prevention model

3.1.1 Signal detection theory and accident prevention model

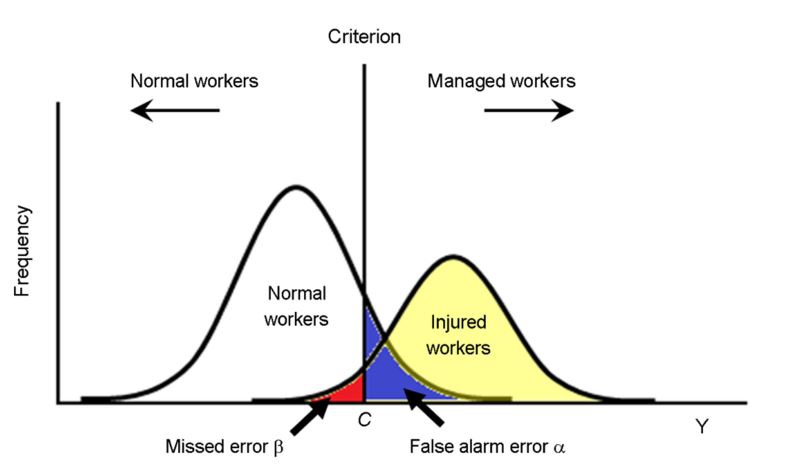

This study aims to draw the accident prevention and control model using the signal detection theory as shown in Figure 1. When the a decision variable is C (criterion) and higher, the worker is judged as the subject of control (managed worker), and when the score is less than c, the worker is judged as a normal worker by applying the signal detection theory (Stanislaw and Todorov, 1999). The decision variable is demonstrated as the number of abnormal variables among the n control variables. Namely, if ith control variable is set up as Xi, and the score 1 and zero are awarded, when the control variable is abnormal and normal, respectively, the decision variable Y demonstrated as the sum of n control variables can be expressed as follows:

= 1, if i th control variable is abnormal range,

= 0, if i th control variable is normal range.

When the distributions of the decision variable of the injured and the uninjured (normal workers) are set up as YInjured and YNormal, respectively, they can be classified into type I error α that judged the uninjured worker as the managed worker, and the type II error β that judged the injured worker as the normal worker as shown in Table 1.

The types of cost by errors can be demonstrated as Cα, cost incurred by type I error α, and Cβ, cost incurred by type II error β, and the total error cost can be indicated as follows:

Total error cost =

Since Cβ is much bigger than Cα in the total error cost, the method to set up the judgment standard to minimize the total error cost is to minimize β, and seek the judgment standard c with smaller α. This study used detection sensitivity, (1-β)/α, as an auxiliary measure of decision making to set up the judgment standard maximizing test power 1-β and smaller value of α, through which the injured were selected as the subjects of control well. If the value of detection sensitivity is bigger, it tends to separate the uninjured and the injured well.

|

Status of judgment Accidental

injury |

Normal

worker |

Managed

worker |

|

Normal worker |

Hit |

False alarm Type I error α |

|

Injured worker |

Miss Type II error β |

Correct |

3.1.2 Development of the accident prevention model

This study developed the accident prevention model using physical examination results for 687 workers in 2006 to select control variables that can explain the status of accidents. Table 2 shows the analysis of the accident prevention model targeting 687 workers, and the number of variables included in the model and the test power 1-β and detection sensitivity (1-β) / α. The accident prevention model having 37 hazard experienced workers and 650 non-hazard experienced workers using 687 workers' health examination data.

When the criterion of decision variable consists of two and more of hazard factors among the five hazard factors, the test power is 64.9%, which is higher than the test power 0.189, compared to the case with three and higher score. When the model consists of four human factors, 62.1% of the injured accepted in the case of setting the criterion as two and higher control score with such variables as the status of heavy smoking, drinking frequency, fatigue and musculoskeletal disorder complaints, and the detection sensitivity value was high at 1.49, and thus it was selected as the most suitable model. When the control model consists of three human factors, 59.5% of the injured accepted in the case of setting the criterion as two and higher with decision variable as drinking frequency, fatigue and musculoskeletal disorder complaints, and the detection sensitivity value was 1.58, and thus it can be used as a suitable model.

No. |

Control

variable |

Characteristics |

Distributions

of Y |

Decision

criterion |

|||||||||||

|

0 |

1 |

2 |

3 |

4 |

5 |

2 or

more |

3 or

more |

||||||||

|

α |

1-β |

(1-β)/α |

α |

1-β |

(1-β)/α |

||||||||||

|

5 |

Smoking,

Drinking, Fatigue, Symptom of MSD, Hearing loss |

Normal |

N |

69 |

287 |

219 |

67 |

8 |

0 |

0.452 |

0.649 |

1.43 |

0.115 |

0.189 |

1.64 |

|

% |

10.6 |

44.2 |

33.7 |

10.3 |

1.2 |

0.0 |

|||||||||

|

Injured |

N |

4 |

9 |

17 |

6 |

1 |

0 |

||||||||

|

% |

10.8 |

24.3 |

45.9 |

16.2 |

2.7 |

0.0 |

|||||||||

|

4 |

Smoking,

Drinking, Symptom of MSD, Hearing loss |

Normal |

N |

211 |

288 |

131 |

20 |

0 |

|

0.233 |

0.459 |

1.97 |

|

||

|

% |

32.5 |

44.3 |

20.2 |

3.1 |

0 |

|

|||||||||

|

Injured |

N |

8 |

12 |

14 |

2 |

1 |

|

||||||||

|

% |

21.6 |

32.4 |

37.8 |

5.4 |

2.7 |

|

|||||||||

|

Drinking,

Fatigue, Symptom of MSD, Hearing loss |

Normal |

N |

77 |

304 |

218 |

48 |

3 |

|

0.414 |

0.594 |

1.43 |

|

|||

|

% |

11.8 |

46.8 |

33.5 |

7.4 |

0.5 |

|

|||||||||

|

Injured |

N |

4 |

11 |

18 |

4 |

0 |

|

||||||||

|

% |

10.8 |

29.7 |

48.6 |

10.8 |

0 |

|

|||||||||

|

Smoking, Drinking, Fatigue, Symptom of MSD |

Normal |

N |

76 |

303 |

214 |

53 |

4 |

|

0.417 |

0.621 |

1.49 |

|

|||

|

% |

11.7 |

46.6 |

32.9 |

8.2 |

0.6 |

|

|||||||||

|

Injured |

N |

5 |

10 |

28 |

11 |

0 |

|

||||||||

|

% |

9.3 |

18.5 |

51.9 |

20.4 |

0 |

|

|||||||||

|

3 |

Drinking, Symptom of MSD, Hearing loss |

Normal |

N |

221 |

314 |

110 |

5 |

|

|

0.177 |

0.432 |

2.44 |

|

||

|

% |

34 |

48.3 |

16.9 |

0.8 |

|

|

|||||||||

|

Injured |

N |

8 |

13 |

15 |

1 |

|

|

||||||||

|

% |

21.6 |

35.1 |

40.5 |

2.7 |

|

|

|||||||||

|

Smoking,

Drinking, Symptom of MSD, |

Normal |

N |

232 |

290 |

115 |

13 |

|

|

0.197 |

0.432 |

2.19 |

|

|||

|

% |

35.7 |

44.6 |

17.7 |

2 |

|

|

|||||||||

|

Injured |

N |

9 |

12 |

13 |

3 |

|

|

||||||||

|

% |

24.3 |

32.4 |

35.1 |

8.1 |

|

|

|||||||||

|

Drinking,

Fatigue, Symptom of MSD |

Normal |

N |

84 |

321 |

211 |

34 |

|

|

0.377 |

0.595 |

1.58 |

|

|||

|

% |

12.9 |

49.4 |

32.5 |

5.2 |

|

|

|||||||||

|

Injured |

N |

5 |

10 |

20 |

2 |

|

|

||||||||

|

% |

13.5 |

27 |

54.1 |

5.4 |

|

|

|||||||||

3.1.3 Verification of the developed model

This study identified the characteristics of human factor control variables of 72 injured workers acquired through the follow up survey from 2006 to 2009 targeting 704 workers who participated in the control model drawing of this study, and reviewed the verification of the hazard prevention and control model.

Table 3 shows the explanation power of the hazard prevention and control model upon the drawing of the model, and review of its verification. According to Table 3, the control models using five and four factors shows similar error probability and explanation power. However, the model using three factors showed different characteristics from the other hazard prevention and control models, and also explanation power was lower. Therefore, it is effective to draw the control model using the five factors in Table 3.

|

No.

of control variable |

Control variable |

Verification 1-β |

|

5 |

Smoking,

Drinking, Fatigue, Symptom of MSD, Hearing loss |

0.680 |

|

4 |

Smoking,

Drinking, Fatigue, Symptom of MSD |

0.639 |

|

3 |

Drinking,

Fatigue, Symptom of MSD |

0.292 |

3.2 Implementation and effects of safety prevention program using the developed model

3.2.1 Implementation of safety prevention program

This study carried out health promotion and support activities to improve five safety and health indices that can affect accident occurrence, namely, drinking frequency, smoking, hearing, fatigue and musculoskeletal disorder complaints from 2007. This study targeted some 900 workers of a production division of a shipbuilding company, and the accident prevention and health promotion activities were executed, based on a workers' health promotion program.

Concerning the activities to cope with drinking frequency and smoking with the high correlation with hazards among everyday life habit indices, a company-wide non-smoking campaign and a sound drinking campaign were implemented at company-wide safety culture establishment level.

As the measure to cope with musculoskeletal disorder complainers with the high correlation with hazards, a musculoskeletal disorder prevention and control program was implemented. Works in a shipyard consist of huge and various processes, and working space is confined mainly. Therefore, the risks of musculoskeletal disorders, such as inappropriate working postures, repetitive works, and excessive energy use, are high, and workers' musculoskeletal disorder complaint ratio is higher than other industries. Therefore, precision survey of work-related harmful factors, medical control, engineering improvement and control measures were steadily implemented.

For hearing preservation control, this study made and operated a hearing control program. A health manager visited the team office concerned on every Monday, and repeatedly educated and inspected the importance of hearing control, how to wear earplugs and the processes and causes causing noise. The health manager offered the information and method to improve the noise on the work environment, and helped the team improve noise environment autonomously, and the case with huge improvement effects was diffused to the other teams during the education.

Also, a psychology counselling room was established and operated so that the musculoskeletal disorder complainers could use. A professional psychology consultant can solve difficult problems that cannot be solved by workers alone through personal counselling, psychology test and evaluation, group program operation and counselling education.

3.2.2 Effects of health promotion and support program

Table 4 shows the effects of accident prevention program using health promotion and support activities. Table 4 shows the total days away from work and accident rate change of the division, as well as the average number of workers working at the division, and the annual average working days. According to Table 4, the total number of workers and total working days increased in 2010, compared to 2006, due to the accident prevention and health promotion activities, but the days away from work fell 87.5%, and accident rate also dropped 71.5% in 2010, compared to 2006, respectively. Namely, the accident prevention and health promotion activities were analysed to hugely contribute to hazard prevention targeting the production division.

|

Year |

2006 |

2007 |

2008 |

2009 |

2010 |

Increment 2010 vs 2006 |

|

No.

of workers |

813 |

800 |

992 |

995 |

919 |

113.0% |

|

Average

work days / year |

289 |

288 |

209 |

290 |

291 |

100.7% |

|

Days

away from work (days) |

4,197 |

4,155 |

3,879 |

2,809 |

523 |

-87.5% |

|

Accident

rate |

2.64% |

2.38% |

1.9% |

1.36% |

0.75% |

-71.5% |

The hazard rate of shipbuilding industry in 2009 was 1.41, which was more than two times higher than mean hazard rate 0.70 of the total industries in South Korea. To reduce hazard rate in the shipbuilding industry, the shipbuilding industry conducted various hazard prevention policies and activities. However, the hazard rate in the shipbuilding industry does how show a downtrend (Pyo and Jeong, 2010).

Physical examination for workers have a function to protect workers' health and prevent diseases. As a result of analysing the measured data related with workers’ physical examination, the accidents occurring in workplaces have the close correlation with workers' health-related human factors, namely, heavy smoking, alcohol habit, hearing, fatigue and musculoskeletal pain complaints. Especially, four major human factors of workers to be controlled in the shipbuilding industry are drinking, smoking, fatigue and musculoskeletal pain complaints, and the control of them is important.

This study implemented the accident prevention activities based on workers' health promotion activities. By implementing the accident prevention activities, based on a health promotion program, to improve the control variables regarded as having the correlation with accident occurrence, namely heavy smoking, alcohol habit, hearing, fatigue and musculoskeletal disorder complaints, targeting one production division of a shipbuilding company for four years, such effects as the reduction of days away from work by 87.5% and accident rate by 71.5% in 2010 were acquired, compared to 2006 before the program was implemented.

Alcohol habits was related with 15~25% of industrial hazards, and drinkers' absence from work was 2.8 times higher than the non-drinkers (Henderson et al., 2005). According to a study on fall accidents reported in the U.S., the fatal fall accidents accounted for 17~53% of the total accidents, due to alcohol habits. If blood alcohol content is 0.05~0.1, the fall accident risk goes up 3 times higher, ten times higher in the case of 0.1~0.15, and more than 60 times higher in the case of over 0.15. In the industries like the shipbuilding industry, where fall accident risk is high, a sound alcohol habits program is continuously operated within the workplace, and a drinking counsellor is employed. Actually, it is important to systematically perform a drinking related policy within a workplace as above.

The fatigue experienced by workers functions as major cause to absence from work arising from disease, or to change of jobs (Janssen et al., 2003). The fatigue causes the following: the maladjustment in everyday life, and reduction of productivity, increase in medical service use, and decline in concentration of workers by working long time during work, negative influence on safety activity perceiving risky situation, causing sleep, insomniac, and increase of accidents on duty. In this manner, workers' fatigue functions as a major factor disturbing industrial safety (Torres-Harding et al., 2002; Hanecke et al., 1998). Therefore, a method to solve problems that cannot be solved by workers alone through an everyday life improving psychology counselling room for the workers with high fatigue and complaining musculoskeletal disorders can be effective.

This study has a limitation in that it targeted only one company in the shipbuilding industry. However, this study is conjectured to be utilized as policy data to prevent industrial hazards in other workplaces, as the study analysed the data that can be acquired through health examination, and drew a hazard prevention and control model.

References

1. Chiolero, A., Wietlisbach, V., Ruffieux, C., Paccaud, F. and Cornuz, J., Clustering of risk behaviors with cigarette consumption: a population-based survey. Preventive Medicine, 42(5), 348-353, 2006.Chiolero, A., Wietlisbach, V., Ruffieux, C., Paccaud, F. and Cornuz, J., Clustering of risk behaviors with cigarette consumption: a population-based survey. Preventive Medicine, 42(5), 348-353, 2006.

Crossref

Google Scholar

2. Choi, Y., Oh, S.Y. and Jeong, B.Y., Roles of health and safety department and its future directions in the shipbuilding industry. Journal of the Ergonomics Society of Korea, 31(1), 203-209, 2012.

Crossref

Google Scholar

3. Dawson, D.A., Heavy drinking and the risk of occupational injury. Accident Analysis and Prevention, 26(5), 655-665, 1994.

Crossref

Google Scholar

4. Gordon, R., Flin, R. and Mearns, K., Designing and evaluating a human factors investigation tool (HFIT) for accident analysis. Safety Science, 43(3), 147-171, 2005.

Crossref

Google Scholar

5. Hansen, H.L. and Pedersen, G., Influence of occupational accidents and deaths related to lifestyle on mortality among merchant seafarers. International Journal of Epidemiology, 25(6), 1237-1243, 1996.

Crossref

Google Scholar

6. Hanecke, K., Tiedemann, S., Nachreiner, F. and Gizech-Sukalo, H., Accident risk as a function of hour at work and time of day as determined from accident data and exposure models for the German working population. Scandinavian Journal of Work, Environment & Health, 24(3), 43-48, 1998.

Crossref

Google Scholar

7. Henderson, M., Glozier, N. and Holland, E.K., Long term sickness absence. British Medical Journal, 330, 802-803, 2005.

Crossref

Google Scholar

PubMed

8. Janssen, N., Kant, I.J., Swaen, G.M.H., Janssen, P.P. and Schroer, C.A., Fatigue as a predictor of sickness absence: results from the Maastricht cohort study on fatigue at work. Occupational and Environmental Medicine, 60, i71-i76, 2003.

Crossref

Google Scholar

9. Jeong, H.W. and Kim, Y.C., A case study on the effect of ergonomics program in shipbuilding industry during the last ten years. Journal of the Ergonomics Society of Korea, 31(1), 191-196, 2012.

Crossref

Google Scholar

10. Jeong, B.Y., Kim, W.J. and Jeong, Y.S., Risk assessment in the shipbuilding industry: Present and the future. Journal of the Ergonomics Society of Korea, 31(1), 143-149, 2012.

Crossref

Google Scholar

11. Kearns, J., Stress at Work, BUPA, London, 1986.

Crossref

12. Kim, D.S., A survey on the implementation of musculoskeletal disorders prevention program in shipbuilding industry. Journal of the Ergonomics Society of Korea, 31(1), 151-156, 2012.

Crossref

13. Lamontagne, A.D., Keegel, T., Louie, A.M., Ostry, A. and Landsbergis, P.A., A systematic review of the job-stress intervention evaluation literature, 1990-2005. International Journal of Occupational and Environmental Health, 13(3), 268-280, 2007.

Crossref

Google Scholar

14. Lee, K.T., The characteristics of industrial accidents in shipbuilding industry. Journal of the Ergonomics Society of Korea, 31(1), 137-142, 2012.

Crossref

15. Oldenburg, M., Baur, X. and Schlaich, C., Occupational risks and challenges of seafaring. Journal of Occupational Health, 52(5), 249-256, 2010.

Crossref

Google Scholar

PubMed

16. Pyo, Y. and Jeong, B.Y., An implementation case of ergonomics program at a shipbuilding company. Journal of the Ergonomics Society of Korea, 26(3), 45-52, 2007.

Crossref

Google Scholar

17. Pyo, Y. and Jeong, B.Y., Correlation analysis between safety and health indices in a shipbuilding industry. Journal of the Ergonomics Society of Korea, 29(6), 897-905, 2010.

Crossref

Google Scholar

18. Sacks, J.J. and Nelson, D.E., Smoking and injuries: an overview. Preventive Medicine, 23(4), 515-520, 1994.

Crossref

Google Scholar

PubMed

19. Stanislaw, H. and Todorov, N., Calculation of signal detection theory measures. Behavior Research Methods, Instruments, & Computers, 31(1), 137-149, 1999.

Crossref

Google Scholar

20. Swaen, G.M.H., Van Amelsvoort, L.G.P.M., Bultmann, U. and Kant, I.J., Fatigue as a risk factor for being injured in an occupational accident: results from the Maastricht Cohort Study. Occupational and Environmental Medicine, 60(1), i88-i92, 2003.

Crossref

Google Scholar

21. Torres-Harding, S.R., Jason, L.A. and Taylor, R.R., Fatigue severity, attributions, medical utilization, and symptoms in persons with chronic fatigue. Journal of Behavioral Medicine, 25(2), 99-113, 2002.

Crossref

Google Scholar

PIDS App ServiceClick here!