eISSN: 2093-8462 http://jesk.or.kr

Open Access, Peer-reviewed

eISSN: 2093-8462 http://jesk.or.kr

Open Access, Peer-reviewed

Sa Kil Kim

, Young Do Koo

, Sangwoo Bahn

10.5143/JESK.2025.44.5.671 Epub 2025 November 07

Abstract

Objective: The aim of this study is to propose procedural functional allocation criteria for determining levels of automation in design of nuclear power plants such as Small Modular Reactors (SMRs).

Background: Increasing the level of automation of high-reliability system is one of the key concerns for safety assessments. In particular, human factors regulations for nuclear power plants require in-depth safety assessments not only of the safety of the automation system, but also of the interaction between the automation system and the human operator. Therefore, determining the level of automation requires the application of new technical criteria that incorporate human factors engineering in design of high-reliability systems.

Method: Existing literatures on function allocation between human and automated systems and relevant industrial technical documents are reviewed systematically. Through the review, supplementary function allocation criteria for determining levels of automation are proposed. The supplementary criteria are structured by closed-loop type algorithm-based procedural process.

Results: A procedural methodology for determining levels of automation is proposed. The procedural criteria consist of 10 main steps and 5 sub-steps.

Conclusion: The proposal of practical technical criteria to ensure safety in design of highly automated system might be applicable to human factors regulatory framework for high-reliability systems such as SMRs.

Application: It is expected to provide practical technical criteria for ensuring safety as increasing the level of automation in SMRs. Specially, the proposed criteria will be utilized for safety review of function analysis and allocation in terms of human factors program review.

Keywords

Function allocation criteria Levels of automation Human factors regulatory framework Small Modular Reactor

Recently, Small Modular Reactor (SMR) is a representative high-reliability and high-automation system in nuclear power industry. SMRs are introducing an innovative operating concept that allows a relatively small number of personnel to operate multiple reactor modules from a single integrated main control room (MCR). This innovative operating concept is advantageous in terms of SMR operation and maintenance costs. An innovative approach to SMR operation and maintenance technology is made possible through the integration of advanced ICT technology. In other words, it is a technology that improves the level of automation in SMRs. The functions of SMRs with improved automation levels should be allocated according to their automation levels as part of human factors engineering program activities.

However, applying existing function allocation criteria or industry practices to perform function allocation for SMRs requiring high levels of automation has limitations. Therefore, new function allocation criteria might be established to accommodate the application of high automation levels. It is urgent to develop technical standards applicable to advanced reactors such as SMRs.

This study investigated and analyzed existing literature on function allocation and relevant industry practices to identify additional or complementary human factors considerations for function allocation that should be considered when applying them to new high-reliability systems being developed with high levels of automation. Furthermore, this study proposed a structured and procedural function allocation methodology that incorporates these additional or complementary function allocation criteria.

Fitts (1951) initiated the field of function allocation research by proposing the Fitts List (MABA-MABA: Men Are Better At / Machines Are Better At). Since then, numerous function allocation criteria and methodologies have been proposed. However, the Fitts List remains a widely used and cited reference. The Fitts List expressed human and machine capabilities through 11 statements. Human strengths include pattern recognition, flexible procedure utilization, inductive reasoning, judgment, and long-term memory. Machine strengths encompass fast and accurate repetitive tasks, handling large-scale force and speed, deductive reasoning (computation), and multitasking. Fundamentally, this approach assigns each function to the entity best suited to perform it.

Winter and Dodou (2014) pointed out that the Fitts List dichotomously divides human and machines and fails to consider organizational contexts or team dynamics in function allocation. However, they also noted that the Fitts List remains foundational technical criteria for function allocation even today. As early as 1951, Fitts already mentioned issues arising from automation, such as reduced human situational awareness, deterioration of technical skills, excessive trust on automation, and problems with control transfer. Ultimately, even as automation levels continue to improve, while the Fitts List retains valid aspects, it suggests that the negative aspects of automation must be appropriately considered in function assignment.

Timothy et al. (2016) comprehensively reviewed theoretical approaches, methodologies, limitations, and new directions for functional allocation within NASA-centric aerospace systems. They argued that the traditional comparative approach based on the Fitts List, focusing on 'who does it better,' is unsuitable for environments requiring complex collaboration. They further emphasized the need to strengthen team-level optimization, dynamic assignment, and situational adaptability in function allocation.

Roth et al. (2019) pointed out that the Fitts List-based approach to task allocation has limitations when applied to highly autonomous systems. This is because a binary allocation method between human and machines can have negative effects on reliability or safety when dynamic environments or unpredictable situations arise. They emphasized that new considerations for function allocation exist from the Human-Autonomy Teaming (HAT) perspective, where human and autonomous systems work together. They argued that the following five factors should be considered in function allocation for highly automated systems: 1) Team-based collaboration between humans and autonomous systems; 2) Dynamic adaptive automation; 3) Trust and transparency; 4) Workload and situation awareness; and 5) Error management and resilience.

Dickerson et al. (2025) conducted a systematic literature review on function allocation in nuclear systems, identifying recurring considerations across the research. The identified considerations include time criticality, uncertainty, human expertise, availability, security, safety, and affordability. They argued that the NUREG/CR-3331-based methodology used in the existing nuclear industry still provides a fundamental framework. However, they emphasized that it lacks quantitative validation and struggles to reflect dynamic assignments, and that a cooperative and complementary perspective between human and automated systems must be considered.

The automation of SMRs can be broadly divided into functional automation and task automation. Functional automation refers to the SMR system performing numerous functions required to achieve its objectives (e.g., safety and power generation) without human intervention. Such functional automation is already being applied to a considerable extent in existing large-scale nuclear power systems. For example, this includes the automation of protective functions, which are central to power plant safety, as well as the automation of feed water control, water level control, and turbine control functions. Task automation refers to a specific system performing work that would otherwise be performed by humans. For example, this includes automation where a system performs specific work defined in operating procedures to check specific conditions and perform tasks under those conditions.

SMRs are being developed with these automation technologies incorporated from the initial conceptual design stage to enable safe and efficient operation. In South Korea, it is known that such automation technologies are being actively introduced and applied in the development of innovative SMRs (i-SMRs).

Improvements in the automation level of SMRs are one of the key concerns in safety reviews from a regulatory perspective. Particularly from a human factors regulation perspective, in-depth safety reviews are required not only for the safety of the automation system itself but also for the interaction between the automation system and the operator. In other words, safety review criteria are needed to determine what level of automation of system functions can ensure the safety of the power plant. These proposals are closely related to technical standards for function allocation between automation functions and operator functions.

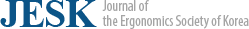

Function allocation is one of the human factors engineering program activities that assigns the functions of complex systems to automated systems and operators. Function allocation has been performed based on the strengths and weaknesses of humans and machines, which were summarized in Fitts' research in the 1950s (Fitts, 1951). NUREG/CR-3331 (1983) is a document that provides technical criteria for function allocation in nuclear power plants and provides a preferred matrix decision-making model for humans and machines. The Figure 1 describes a direction for function allocation criteria for improving automation levels based on NUREG/CR-3331 (Kim and Koo, 2025).

The Ua area represents functions where automation performance is too low to consider automation, and such functions are assigned to humans.

The Uh area is an area where human limitations prevent assignment to humans, and automation functions are required.

The Uah area is an area where assignment to both humans and automated systems is impossible, and a reevaluation of function design is necessary.

The Ph area represents functions where human advantages are leveraged, and if there is no alternative automation system to replace them, they are assigned to humans.

The Pa area represents functions that can be designed for automation systems and are economically viable, and unless there is a special reason, they are assigned to automation systems.

The Pha area represents functions that can be assigned to both humans and automation systems, and they are assigned to either humans or automation systems based on cost or preference.

The functional allocation criteria provided in NUREG/CR-3331 (1983) are broadly divided into those for humans, automated systems, or areas shared by humans and automated systems. In the case of nuclear power plants, including SMRs, where automation levels are improving, there are limitations to applying the functional allocation criteria of NUREG/CR-3331 (1983) as it is. This is because nuclear power plants with high automation levels must be allocated according to at least the following five categories of automation levels (NUREG-0700, Rev. 3, 2020), and functional allocation based on automation levels cannot be performed simply based on the advantages and disadvantages of humans and automated systems.

Ⅰ. Manual Operation: No automation, operators manually perform all tasks.

Ⅱ. Shared Operation: Automatic performance of some tasks, operators perform some tasks manually.

Ⅲ. Operation by Consent: Automatic performance when directed by operators to do so, under close monitoring and supervision. Operators monitor closely, approve actions, and may intervene to provide supervisory commands that automation follows.

Ⅳ. Operation by Exception: Essentially autonomous operation unless specific situations or circumstances are encountered. Operators must approve of critical decisions and may intervene.

Ⅴ. Autonomous Operation: Fully autonomous operation. System cannot normally be disabled but may be started manually. Operators monitor performance and perform backup if necessary, feasible, and permitted.

Design concept of levels of automation has been discussed around over 30 years ago. Sheridan (2002) offered 8 levels of automation as shown in Table 1. Also, Billings (1997) proposed the division of responsibilities for characterizing 7 levels of automation as shown in Table 2. This division of levels of automation could be applied to general industry, but research has been done on the appropriate level of automation for the nuclear industry. O'Hara and Higgins (2010) found examples of nuclear power plant automation at every level as shown in Table 3.

|

Levels |

Description |

|

1 |

The computer offers no assistance; the human must do it all |

|

2 |

The computer suggests alternative ways to do the task |

|

3 |

The computer selects on way to do the task and (see Level 4) |

|

4 |

Executes that suggestion if the human approves, or (see Level 5) |

|

5 |

Allows humans a restricted time to veto before automatic

execution, or (see Level 6) |

|

6 |

Executes automatically, then necessarily informs the human, or

(see Level 7) |

|

7 |

Executes automatically, then informs the human only if asked |

|

8 |

The computer selects the method, executes the task, and ignores

the human |

|

Levels |

Role of automation |

Role of human |

|

Autonomous operation |

Fully autonomous operation. Human not usually |

Human generally has no role in operation, |

|

Operation by exception |

Essentially autonomous operation unless specific |

Human must approve of critical decisions |

|

Operation by consent |

Full automatic control under close monitoring |

Human monitors closely, approves actions, |

|

Operation by delegation |

Automatic control when directed by human |

Human provides supervisory commands |

|

Shared control |

Automatic control of some

functions task. |

Humans control some

functions/tasks. |

|

Assisted manual control |

Primarily manual control with some |

Human manually controls with assistance |

|

Direct manual control |

No automation is used. |

Human manually controls all functions |

|

Levels |

Automation functions |

Human functions |

NPP example |

|

Manual |

No automation |

Operators manually perform all |

Demineralized water |

|

Shared |

Automatic performance of some functions/tasks |

Manual performance of some |

Suppression pool cooling |

|

Operation

by |

Automatic performance when directed |

Operators monitor closely, approve |

Reactor startup |

|

Operation

by |

Essentially autonomous operation |

Operators must approve of critical |

Automatic Depressurization |

|

Autonomous |

Fully autonomous operation. System |

Operators monitor performance |

Reactor Protection System |

As a result, it is necessary to prepare human factors regulatory measures according to the levels of automation. In particular, in the case of advanced reactors such as SMRs, the levels of automation may be different for each development system and the concept of operation may be different, so it is necessary to provide a basis for developers to demonstrate safety through functional analysis and function allocation.

Increasing the level of automation of SMRs is one of the key concerns for safety assessments from a regulatory perspective. In particular, human factors regulations require in-depth safety assessments not only of the safety of the automation system, but also of the interaction between the automation system and the human operator. The interaction between automated systems and human operators is called 'adaptive automation.' The term for whether automation is designed to always function at the same level or whether the level can change, based on defined triggering conditions, such as operator request, operator state, or plant condition. When tasks can be flexibly performed by human or machine agents, the automation is said to be adaptive (NUREG-0700, Rev. 3, 2020). Therefore, it is necessary to establish a technical basis for human factors regulations for adaptive automation. In particular, the definition of the safety functions of SMRs and the power generation functions that can affect the safety functions, as well as the allocation of each defined function, are closely related to adaptive automation.

Approaching adaptive automation from a human factors regulatory perspective fundamentally starts with how increasing the level of SMR automation can impact safety. The increased level of automation has highlighted the following positive perspectives, generally:

Increasing the level of automation ultimately leads to improved system performance. Improved system performance ultimately leads to improved safety;

Increasing the level of automation reduces the burden on operators. Automating the most demanding operator tasks can improve safety;

Increasing the level of automation can minimize the operator tasks and thus minimize the frequency of human error. By reducing the frequency of human error, safety is improved;

Increasing the level of automation increases the automation of operations and maintenance tasks. By reducing the number of safety degradation factors that can occur during operations and maintenance tasks, safety is improved.

The positive perspectives above seem to point in the same direction: increasing automation and improving safety go hand in hand. However, it has long been recognized that for safety-critical and complex systems, including SMRs, increasing the level of automation can lead to the following concerns.

The problem of situational awareness as the level of automation increases is that the more complex and dynamic the system, the less successful human performance can be guaranteed (Endsley, 1996).

Low workload at high levels of automation can lead to boredom and fatigue due to a lack of cognitive involvement (Kaber and Endsley, 2004).

High workloads that are demanded in a hurry induce a rapid decline in situational awareness, which leads to poor job performance and makes it difficult to recognize changes in the system (Endsley, 1993).

Automation systems support operator performance. However, if the automation system deteriorates or fails, the operator may no longer trust the automation system and overall task performance may not improve (O'Hara and Higgins, 2020).

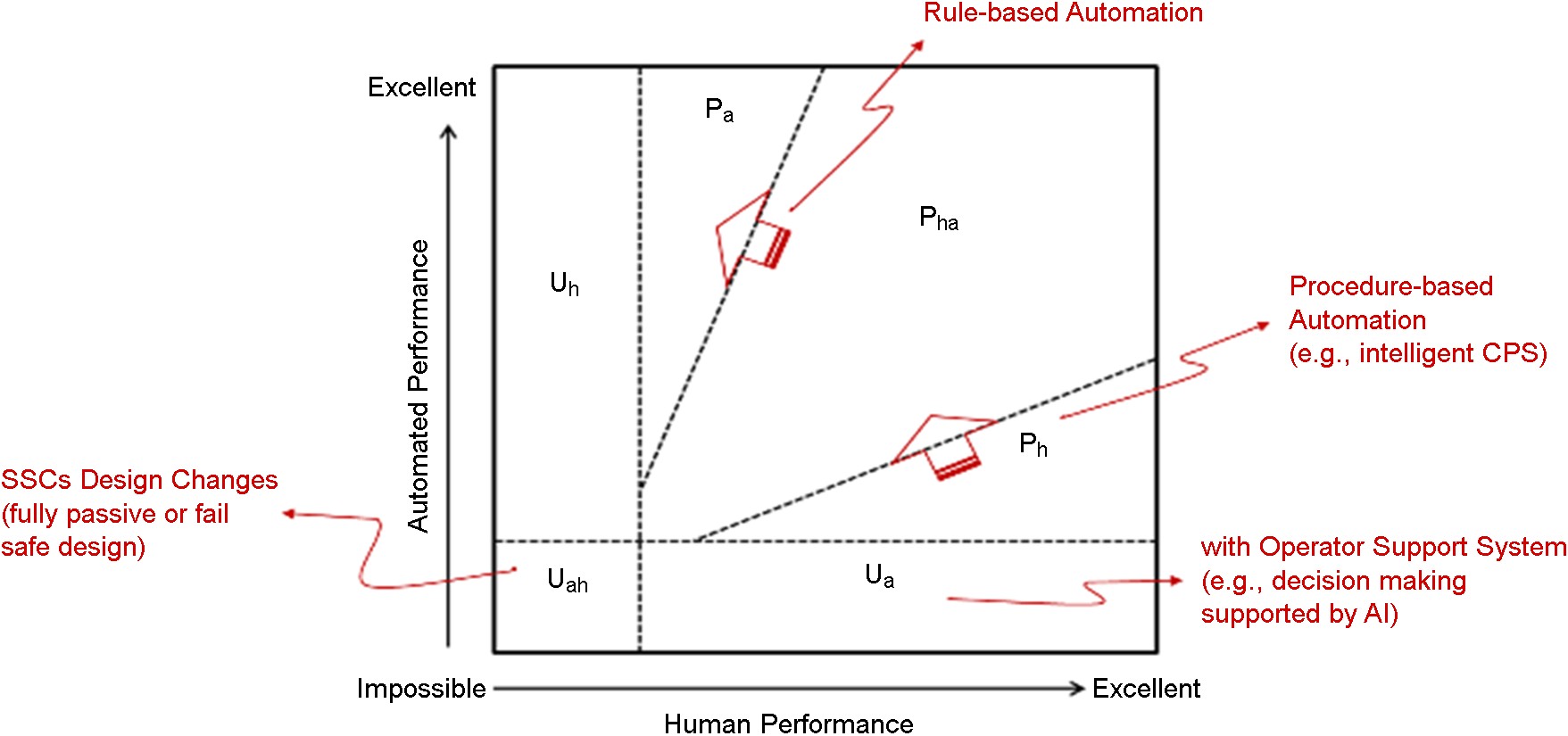

Research on functional allocation criteria applicable to the design of nuclear power plants with high levels of automation has been limited over the past 20 years, but there are two representative and significant studies. The first study by Parasuraman et al. (2000) is a cognitive engineering approach to determining the level of automation based on the type of human interaction as shown in Figure 2. This study provided functional allocation criteria to consider when automating human functions based on human information processing models. The second study is by Jeffrey et al. (2015) who proposed considering team dynamics in functional allocation. Jeffrey et al. (2015) suggest that functional allocation should consider not only the individual cognitive and computational abilities of humans and automation but also the social factors that affect teamwork. The approach that while teams composed of humans have mutual trust, teams composed of humans and automation systems have biases in trust is an interesting and important point.

This study derived technical criteria for human performance aspects in function allocation for automation levels through a systematic review of existing literatures. For designing systems with high automation levels, such as SMRs, it organized the human performance aspects that need to be supplemented to the existing function allocation criteria, such as NUREG/CR-3331 (1983), when establishing function allocation criteria for automation levels. These supplementary aspects were applied to the procedural allocation methodology for automation levels.

When assigning functions in nuclear power plants designed with various automation levels, such as SMRs, the followings should be considered.

4.1 Mental workload

Automated systems involved in the processes of information recognition, analysis, and decision-making affect the mental workload of operators. If the amount of information that the operator must monitor is large, that information must be processed and provided to the operator in a reduced amount of analyzed information. A large amount of information means that there is a high degree of uncertainty regarding the status or situation of the power plant that the operator must understand, and only information centered on the results of analysis combining individual monitoring variables at the power plant site should be provided to reduce that uncertainty.

Additionally, if there are too many options for the decision-making process to determine the control actions that the operator must perform based on the monitoring information, the optimal alternative with the highest priority in terms of safety must be provided to reduce the operator's mental workload. Therefore, the considerations for function allocation to optimize the operator's mental workload are summarized as follows.

Automation systems must monitor individual variables at the power plant site, process them into status and situation information about the power plant, and provide this information to operators.

Automation systems should quantitatively provide operators with uncertainty regarding the plant's status and situation information.

Automation systems should provide operators with options for control actions based on the plant's status and situation information. If there are two or more options, priority information should be provided based on safety.

4.2 Situation awareness

The functions of automated systems can have a positive or negative impact on the situation awareness of operators. Situation awareness refers to the extent to which operators can predict future conditions based on the current status of the power plant (Endsley, 1996; Endsley, 1993). Therefore, if the information provided by the automated system regarding the current status of the power plant is contaminated, operators will be unable to accurately predict future conditions. Furthermore, if the operator is unaware of the functions performed automatically by the automation system, the operator will predict the status of the power plant based on limited information, resulting in reduced situation awareness. However, if the automation system can accurately provide the operator with information on the current status and near future status of the power plant, the operator's situation awareness can be greatly improved. Therefore, the considerations for assigning functions to improve the operator's situation awareness are summarized as follows.

Automation systems should provide operators with supportive information that helps them understand the plant's status or situation.

Automation systems should provide operators with information about the plant's near-future status or situation through visual and auditory means.

Automation systems should provide operators with historical data and technical background information about the automated processes.

4.3 Complacency

Operators can view automated systems as team members who assist in power plant operations. In other words, operators and automated systems form a team. Operators develop a level of trust in automated systems, and that level of trust can vary depending on the situation. If the operator loses trust in the automated system, the automated system is no longer a team member of that operator team. Conversely, if the operator places excessive trust in the automated system, they may become complacent about the automated system's performance and fail to recognize functional failures in the automated system. Therefore, the functional allocation considerations related to complacency can be summarized as follows.

The automated system must provide the operator with situational reliability information regarding the functions it performs automatically. The situational reliability information of the automated system must be provided based on the uncertainty information of the information acquired by the automated system.

The operator must periodically check the performance history information and technical background information of the automated system.

The automated system must provide means of interaction to communicate with the operator.

4.4 Skill degradation

The introduction of automated systems positively supports the plant operators' duties, enabling them to operate the plant efficiently and safely. However, in the long term, the introduction of automated systems may lead to a decline in the skills required for plant operation. While the introduction of automation systems changes the duties of plant operators, in the event of a malfunction or failure of the automation system, plant operators must be able to perform the functions of the automation system. Ultimately, the allocation of functions between automation systems and plant operators must consider the prevention of skill degradation among plant operators. The following summarizes the considerations for function allocation related to this issue.

If operators must be prepared for the degradation or failure of functions performed by automated systems, the level of automation for such functions should not be too high.

Automated systems should provide operators with the technical logic and processes involved in performing functions, ensuring that operators maintain the ability to perform such functions directly.

4.5 Automation reliability

The reliability of automation systems affects the mental workload, situational awareness, and complacency of operators. Automation reliability must be sufficiently acceptable in terms of safety. The inherent reliability of automation systems must be sufficiently ensured at the design stage. If automation reliability may be affected by the operating environment, information on changes in reliability must be obtained. Considerations for functional allocation related to automation reliability are as follows.

If automation reliability is not ensured, the function must be assigned to the operator.

Even if automation reliability is ensured, if it may change depending on the operating environment, the operator must be aware of the changing reliability information.

4.6 Costs of automation failure

Automation functions can provide economic and operational efficiency by replacing the duties of operators. However, it is impossible to exclude the additional duties of operators in preparation for the failure of automation functions. In addition, issues related to power plant safety that may arise due to automation failure must be managed in terms of risk. Risk management refers to the expected costs that may arise due to automation failure. Considerations for assigning functions in terms of automation failure costs are as follows.

Operator backup functions in preparation for automation failures must be considered from a safety perspective. In other words, if the costs of automation failures exceed the benefits in terms of risk, the automation functions should be considered as operator functions.

If the costs required to maintain operator functions in preparation for automation failures are high, the functions should be assigned to operators.

4.7 Human factors regulatory safety reviews

In the case of complex nuclear power plants where automation systems are applied, safety must be prioritized, so the level of automation may vary depending on the status or situation of the plant. Therefore, it is reasonable to consider the variability of the automation level when assigning functions. Adaptive automation, which is a concept of situation-dependent automation, should be prioritized when assigning functions related to the automation level.

The human factors regulatory approach to adaptive automation in SMRs is that even if the level of automation in SMRs is improved, the concept of operation without operators cannot be permitted. This basic regulatory approach can be summarized in the following three points (Kim and Koo, 2025).

High-level supervision and management functions should be assigned to operators rather than automation systems.

Operators must be able to respond appropriately to unplanned or unforeseen events or accidents.

Operators must be able to respond appropriately to functional degradation or failure of automated systems.

Ultimately, the focus of safety reviews for adaptive automation is to verify that the optimal level of automation has been set in terms of safety. The optimal level of automation is directly related to the functional allocation criteria set by the operator. Therefore, reasonable technical criteria must be established to appropriately allocate functions defined according to the design characteristics of SMRs (especially safety functions) to automation systems and operators. The safety review of adaptive automation needs to be based on the following functional allocation criteria (Kim and Koo, 2025).

Fully automation functions must ensure safety without operator intervention under any circumstances. However, means to monitor the performance status of fully automated functions must be provided.

Automation functions involving knowledge-based decision-making should be minimized. However, automation functions may be assigned as a means of supporting knowledge-based decision-making.

For functions involving tasks that are expected to impose a high cognitive load due to the technical limitations of automation, automation functions should be added to tasks that allow operators to perform those functions with minimal cognitive burden by accepting procedural information.

When automation of functions minimizes the operator's workload, the operator must be able to continuously monitor the status of automated functions. Additionally, immediate operator intervention must be possible in the event of a malfunction or failure of automated functions.

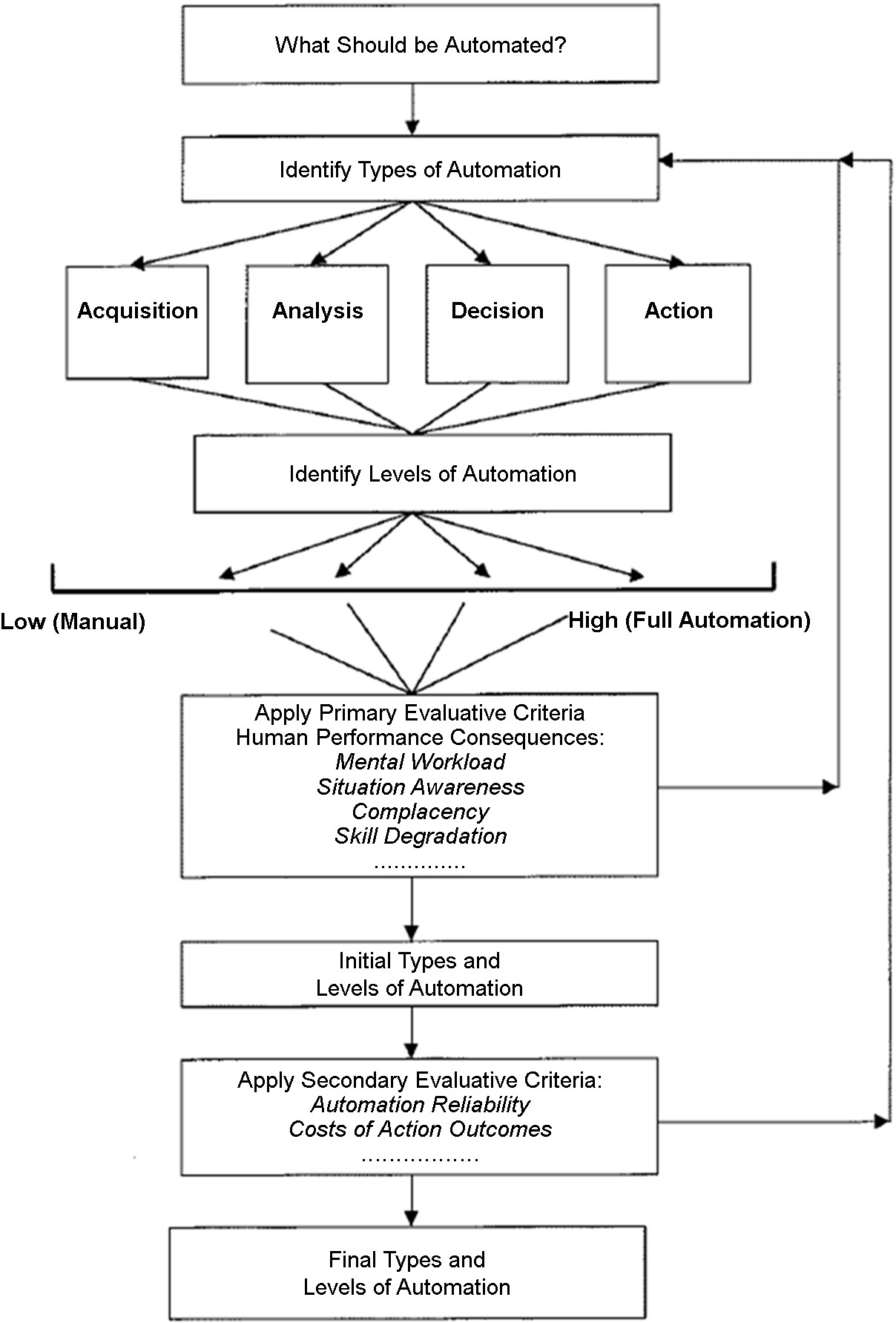

The criteria for assigning automation levels were developed by supplementing existing criteria to incorporate human factors considerations. The proposed criteria and methodology determine the automation level for functions in advanced nuclear power plants through specific criteria and procedures.

The proposed criteria and method constitute a closed-loop procedural approach for determining the automation level of all functions derived during the design of advanced nuclear power plants. This involves an infinite iteration process until a specific function is assigned to a specific automation level.

The proposed criteria and methodology comprise a total of 10 steps as follow, including additional steps within specific steps (e.g., Step 2-1), resulting in a total of 16 steps (see Figure 3).

Step 1: Is automatic control absolutely necessary?

Step 2: Is automatic control technically feasible?

Step 2-1: Are there manual backup regulatory requirements?

Step 2-2: Does it affect human performance?

Step 3: Is manual control absolutely necessary?

Step 4: Is manual control feasible?

Step 4-1: Is automated support required?

Step 5: Re-confirm core functions

Step 6: Is functional separation possible?

Step 7: Is automatic control preferred?

Step 8: Is automatic control justified?

Step 8-1: Is manual backup required?

Step 8-2: Does it affect human performance?

Step 9: Is manual control preferred?

Step 10: Is manual control justified?

Step 10-1: Is an automatic mode required?

Function allocation using the proposed criteria and method is assigned to the following five automation levels:

Automation level 1: Manual operation;

Automation level 2: Shared operation;

Automation level 3: Operation by consent;

Automation level 4: Operation by exception;

Automation level 5: Autonomous operation.

Figure 3 depicts the process of allocating defined functions to automation levels. Functions defined in the early stages of system design require determination of the automation level needed to achieve them. This involves: a) determining whether automation is required (step 1-2), b) determining whether manual performs are required (step 3-4), c) determining the preference for automation or manual performs (step 5-10), and d) assign the most suitable automation level (sub-steps, e.g., step 2-1).

Innovative SMRs developed in Korea must ensure safety from a regulatory perspective in order to be competitive in the global market. Therefore, human factors review guidelines for large pressurized water reactors need to be improved so that they can also be used in the review of SMRs. From a human factors regulatory perspective, the introduction of a multi-module integrated control room operating concept may give rise to new human factors issues. In particular, as automation levels improve, functional assignments must be performed according to automation levels, and new standards for functional assignments for adaptive automation must be established. The functional allocation considerations for automation levels proposed in this study are expected to serve as a technical foundation for safety reviews of functional assignments in nuclear power plants designed with high automation levels, such as SMRs.

Additionally, the proposed criteria and methodology address the limitations of existing function assignment standards and procedures (based on NUREG/CR-3331), which are centered on large conventional nuclear power plants and cannot be applied to advanced nuclear power plants like SMRs.

The proposed criteria and methodology are expected to be applicable to the design of innovative SMRs under development domestically, as well as non-PWR Generation IV reactors (e.g., high-temperature gas reactors, molten salt reactors, micro reactors, etc.).

With approximately 80 types of SMRs under development globally, technological competition to dominate the world market is accelerating. This approach avoids random automation design and enables the acquisition of automation design technology through systematic and safe determination of automation levels.

References

1. Billings, C., Aviation Automation: The search for human-centered approach, Mahwah, NJ: Lawrence Erlbaum Associate, Incorporated, 1997.

Google Scholar

2. Dickerson, K., Watkins, H., Hartle, B. and Kovesdi, C., Function allocation: Myths, process, and merging methods, NPIC & HMIT 2024, American Nuclear Society, 2025.

Google Scholar

3. Endsley, M., A survey of situation awareness requirements in Air-to-Air combat fighters, International Journal of Aviation Psychology, 3(2), 157-168, 1993.

Google Scholar

4. Endsley, M., Automation and situation awareness. In R. Parasuraman and M. Mouloua (Eds.) Automation and Human Performance: Theory and Applications (pp. 163-181). Mahwah, NJ: Lawrence Erlbaum, 1996.

Google Scholar

5. Fitts, P.M., Human engineering for an effective air-navigation and traffic-control system. National Research Council, Washington, DC, 1951.

Google Scholar

6. Jeffrey, C.J., O'Hara, J.M., Hugo, J.V. and Oxstrand, J.H., Function allocation for humans and automation in the context of team dynamics, Procedia Manufacturing, 3, 6th International Conference on AHFE 2015, 1225-1232, 2015.

Google Scholar

7. Kaber, D. and Endsley, M., The effects of level of automation and adaptive automation on human performance, situation awareness and workload in a dynamic control task, 2004.

Google Scholar

8. Kim, S.K. and Koo, Y.D., Regulatory Basis for the Safety Evaluation of Increased Level of Automation in relation to the Concept of Multi-module Integrated MCR Operation, NPIC & HMIT 2025 Proceedings, 944-949, 2025.

9. NUREG/CR-3331, A Methodology for allocating nuclear power plant control functions to human or automatic control, U.S. Nuclear Regulatory Commission, 1983.

10. NUREG-0700, Rev. 3, Human-System Interface Design Review Guidelines, U.S. Nuclear Regulatory Commission, 2020.

Google Scholar

11. O'Hara, J.M. and Higgins, J., Human-system interfaces to automatic systems: Review guidance and technical basis, BNL-91017-2010, 2010.

Google Scholar

12. O'Hara, J.M. and Higgins, J., Adaptive Automation - Current status and challenges, RIL 2020-05, U.S. Nuclear Regulatory Commission, 2020.

13. Parasuraman, R., Sheridan, T.B. and Wickens, C.D., A model for types and levels of human interaction with automation, IEEE Transactions on System, Man, and Cybernetics – Part A: System and Humans, 30(3), 286-297, 2000.

Google Scholar

14. Roth, E.M., Sushereba, C., Militello, L.G., Diiulio, J. and Ernst, K., Function allocation consideration in the era of human autonomy teaming, Journal of Cognitive Engineering and Decision Making, 13, 199-220, 2019.

Google Scholar

15. Sheridan, T., Humans and Automation: System design and research issues, New York: Wiley & Sons, 2002.

16. Timothy, A.L., Arwa, S.A., Nelson, M.G. and Ronald, J.D., A review of function allocation and en route separation assurance, NASA/TM-2016-219343, 2016.

Google Scholar

17. Winter, J.C.F. de and Dodou, D., Why the Fitts list has persisted throughout the history of function allocation, Cognitive Technology Work, 16, 1-11, 2014.

Google Scholar

PIDS App ServiceClick here!